Picture this: It’s Monday morning, and you’re staring at a report showing missed deliveries, excess inventory, and rising production costs. Sound familiar? If you’re nodding your head, you’re not alone. But what if there was a way to turn this nightmare into a dream come true? Enter supply chain analytics in manufacturing – your secret weapon for operational excellence.

In today’s fast-paced, data-driven world, supply chain analytics in manufacturing is revolutionizing how companies operate, make decisions, and stay competitive. It’s not just a buzzword; it’s a game-changer that’s reshaping the entire manufacturing landscape. But what exactly is supply chain analytics in manufacturing, why should you care, and how can you implement it effectively? Let’s dive in and explore this transformative technology.

Issues in Traditional Manufacturing Methods

Before we explore the role of manufacturing analytics, let’s take a moment to acknowledge the pain points you’re likely facing with traditional manufacturing methods:

- Inventory Mismanagement: The constant struggle of having too much stock tying up capital or too little leading to stockouts and dissatisfied customers.

- Production Inefficiencies: Unexpected machine downtime, quality issues, and inefficient processes eating into your profits and productivity.

- Demand Forecasting Challenges: The ongoing battle to predict what your customers will want next, leaving you constantly playing catch-up and missing opportunities.

- Supplier Relationship Struggles: Late deliveries, quality issues, and lack of visibility into your supplier network causing endless frustration and delays.

- Logistics Nightmares: Shipping delays, rising transportation costs, and lack of real-time tracking leaving you in the dark about your products’ whereabouts.

- Data Silos: Valuable information trapped in different departments or systems, preventing a holistic view of your operations.

- Reactive Decision Making: Constantly putting out fires instead of preventing them, leading to higher costs and missed opportunities.

These challenges aren’t just inconveniences – they’re roadblocks to growth, profitability, and competitiveness in an increasingly global market. But there’s good news: supply chain analytics in manufacturing offer a powerful solution to these age-old problems.

The Advent of Supply Chain Analytics in Manufacturing

So, what exactly is supply chain analytics in manufacturing? Think of it as a digital crystal ball for your operations. It’s the art and science of collecting, analyzing, and interpreting data from every nook and cranny of your supply chain to make smarter, faster, and more profitable decisions.

Supply chain analytics in manufacturing isn’t just about crunching numbers – it’s about turning those numbers into actionable insights that can transform your business. It’s like having a team of genius analysts working 24/7 to optimize every aspect of your operation.

This revolutionary approach of analytics in manufacturing combines advanced technologies like artificial intelligence, machine learning, and big data analytics with traditional supply chain management principles. The result? A powerful tool that can predict trends, identify inefficiencies, and suggest optimizations in real-time.

Benefits of Supply Chain Analytics in Manufacturing: Your Ticket to Operational Excellence

Well, if you think that supply chain analytics is only about numbers and stats; well, you need to rethink! The benefits of implementing supply chain analytics in manufacturing are far-reaching and transformative.

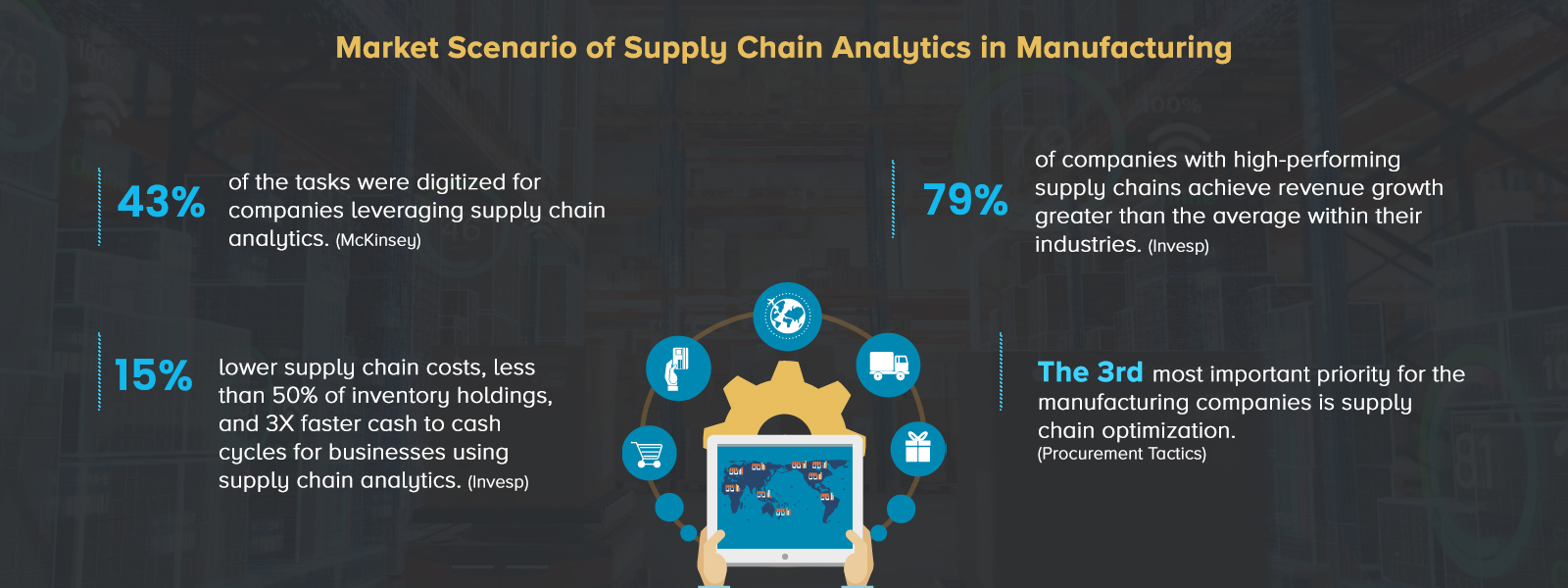

As per a trusted source, 79% of companies with high-performing supply chains achieve greater revenue growth than the average for their industry. And that’s not all!

Here’s how supply chain analytics can revolutionize your operations:

Enhanced Visibility

Enhanced Visibility

Imagine having x-ray vision for your entire supply chain. That’s what supply chain analytics in manufacturing offers. No more guessing where your raw materials are, or when they’ll arrive. No more wondering about production status or delivery schedules. With real-time data at your fingertips, you’ll have a crystal-clear view of every aspect of your operation.

- Spot potential issues before they become problems

- Identify opportunities for improvement

- Make informed decisions based on a complete picture of your supply chain.

It’s like turning on the lights in a dark room – suddenly, everything becomes clear.

Read More: Enhance your business operations with Supply Chain Visibility Platform Development to achieve real-time tracking, predictive analytics, and end-to-end transparency.

Improved Forecasting

Improved Forecasting

Say goodbye to the crystal ball and hello to precision forecasting. Supply chain analytics in manufacturing doesn’t just look at your historical sales data; it considers market trends, economic indicators, social media sentiment, and even weather patterns to predict demand with uncanny accuracy.

- Imagine knowing exactly how much of each product you’ll need to produce next month, next quarter, or next year.

- No more overproduction leading to excess inventory, no more underproduction leading to lost sales.

- You’ll be able to align your production perfectly with demand, maximizing profits and minimizing waste.

Optimized Inventory Management

Optimized Inventory Management

Picture this: you have the right amount of inventory – not too much tying up capital or too little risking stockouts. That’s the power of supply chain analytics in manufacturing.

- By analyzing demand patterns, lead times, and even supplier reliability, you can determine the optimal inventory levels for each product

- Reduce your carrying costs while ensuring you always have what you need on hand

It’s like having a just-in-time inventory system on steroids, perfectly balanced to meet your needs and your customers’ demands.

Read More: Discover how AI inventory management software is transforming inventory operations by automating stock tracking, reducing waste, and optimizing supply chains for maximum profitability.

Streamlined Production

Streamlined Production

Imagine your production line running like a well-oiled machine, with no hiccups, no bottlenecks, and no wasted time. Supply chain analytics in manufacturing makes this a reality. By analyzing production data in real-time, you can identify inefficiencies, optimize schedules, and improve overall equipment effectiveness.

- Spot bottlenecks before they slow you down

- Optimize your production schedules to maximize efficiency

- Ensure that every minute of production time is used to its fullest potential

It’s like having a super-efficient production manager who never sleeps, always spotting ways to improve.

Proactive Maintenance

Proactive Maintenance

Picture a world where your machines never break down unexpectedly. With supply chain analytics in manufacturing, this becomes possible. By analyzing data from sensors on your equipment, you can predict when a machine will fail before it does.

- Schedule maintenance at the most opportune times

- Prevent unexpected breakdowns

- Extend the life of your assets

It’s like having a crystal ball for your machinery, allowing you to act before problems occur, not after.

Enhanced Quality Control

Enhanced Quality Control

Imagine catching every quality issue before your products leave the factory. Supply chain analytics in manufacturing makes this possible. By analyzing production data in real-time, you can spot quality issues as they emerge, not after your products have been shipped.

- Identify the root causes of quality problems

- Make adjustments on the fly

- Ensure that only top-quality products reach your customers

It’s like having a thousand eagle-eyed quality inspectors working 24/7, catching every imperfection.

Improved Supplier Management

Improved Supplier Management

Picture having a scorecard for every supplier, based on objective data rather than gut feel. With supply chain analytics in manufacturing, you can:

- Track supplier performance in real-time

- Measure factors like on-time delivery, quality, price competitiveness, and more

- Use this data to have more productive conversations with your suppliers, identifying areas for improvement and recognizing top performers

It’s like having a relationship counselor for your supplier relationships, helping you build stronger, more productive partnerships.

Optimized Logistics

Optimized Logistics

Imagine your products always taking the fastest, most cost-effective route with your customers. Analytics in manufacturing makes this a reality. By analyzing shipping data, traffic patterns, and even weather forecasts, you can optimize your logistics operations in real-time.

- Plan the most efficient routes

- Improve load planning to maximize truck capacity

- Track shipments in real-time to provide accurate ETAs to your customers

It’s like having a logistics superhero, ensuring your products always arrive on time and at the lowest possible cost.

Better Decision Making

Better Decision Making

Picture making every decision with the confidence of having all the facts at your fingertips. Custom manufacturing analytics software provides you with data-driven insights for every aspect of your operation.

- No more relying on gut feeling or outdated reports

- Leverage real-time, accurate data to inform every decision

- Get analytics on strategic choices about new product lines and tactical decisions about daily production schedules

It’s like having a team of expert advisors by your side 24/7, always ready with the insights you need to make the best possible decisions.

In short, in today’s fast-paced, ever-changing manufacturing landscape, supply chain analytics isn’t just a nice-to-have – it’s a must-have for survival and success.

It’s the key to unlocking efficiencies, reducing costs, improving quality, and staying ahead of the competition. With supply chain analytics in manufacturing, you’re not just keeping up with the future of manufacturing – you’re leading the way.

You don’t believe us? Here’s a stellar case study that shows the transformative power of analytics in manufacturing!

Case Study: Transforming AMZ Prep’s Supply Chain with Analytics

Problem:

AMZ Prep, a leading FBA prep service provider, faced significant challenges in managing their supply chain due to manual processes. These outdated methods, including paper records and spreadsheets, led to labeling and packing errors, inefficiencies, and a lack of real-time visibility. These issues hindered operational efficiency and affected customer satisfaction.

Solution:

Matellio implemented a comprehensive digital transformation solution, emphasizing supply chain analytics. This involved replacing manual methods with a centralized digital system for managing merchant onboarding, inbound consignments, inventory management, and order fulfillment.

The new system integrated supply chain analytics, providing real-time insights into operations, enabling better decision-making, and ensuring compliance with Amazon’s evolving guidelines.

The solution’s scalability allowed AMZ Prep to accommodate more merchants and streamline operations. Additionally, the system facilitated automated retrieval and printing of FNSKU codes and shipment labels, further enhancing operational efficiency.

Outcome:

The integration of supply chain analytics transformed AMZ Prep’s operations, significantly reducing errors and processing times, leading to cost savings and enhanced customer satisfaction.

Real-time updates and data analytics kept AMZ Prep compliant with Amazon’s guidelines, avoiding penalties and disruptions. Most importantly, supply chain analytics empowered AMZ Prep to continuously monitor performance, make informed decisions, and optimize their supply chain, setting the stage for sustained success in the competitive FBA market.

Want a Similar Transformation for Your Company Using Supply Chain Analytics?

Contact Us

Technology Trends Enhancing Supply Chain Analytics in Manufacturing

Now that you’ve seen how supply chain analytics can revolutionize manufacturing operations, let’s explore the cutting-edge technologies that are taking this power to the next level. These innovations are not just futuristic concepts – they’re tools that forward-thinking manufacturers are already using to gain a competitive edge.

Artificial Intelligence (AI) and Machine Learning (ML)

Imagine having a virtual data scientist working tirelessly to uncover insights from your supply chain data. That’s what AI and ML bring to the table. As per a trusted source, AI-powered supply chains are 67% more efficient than traditional supply chains. But what can AI integration services offer to your business?

- Predictive analytics on steroids: AI algorithms can process vast amounts of data to forecast demand, predict maintenance needs, and optimize inventory with unprecedented accuracy.

- Autonomous decision-making: Advanced AI systems can make real-time decisions, adjusting production schedules or reordering supplies without human intervention.

- Continuous improvement: ML models learn from each decision and outcome, constantly refining their predictions and recommendations.

Read More: How Can AI Help in Enhancing Supply Chain Management?

Internet of Things (IoT)

Picture your entire supply chain coming alive with data. That’s possible with IoT development services! Connected devices and sensors provide real-time data from across the supply chain, enabling more accurate and timely analytics.

- Real-time visibility: Track the location and condition of raw materials, work-in-progress, and finished goods in real-time.

- Predictive maintenance: Sensors on machinery can detect early signs of wear, allowing you to schedule maintenance before breakdowns occur.

- Environmental monitoring: Ensure optimal conditions for sensitive materials or products throughout the supply chain.

5G Networks

Imagine having lightning-fast, ultra-reliable connectivity across your entire operation. That’s what 5G in supply chain analytics offer to your business! Faster, more reliable connectivity enables the transmission of larger volumes of data in real-time, enhancing analytics capabilities.

- Real-time data processing: Enable instantaneous data transmission from IoT devices, supporting split-second decision-making.

- Enhanced remote monitoring: Conduct detailed, real-time inspections of distant facilities or in-transit goods.

- Improved collaboration: facilitate seamless communication and data sharing across your global supply network.

Digital Twins

Picture having a virtual replica of your entire supply chain that you can experiment with risk-free. That’s what digital twin, a part of IIoT services, offers to your business! Virtual replicas of physical assets or processes allow for more accurate simulations and scenario planning.

- Scenario planning: Test different strategies and see their impact before implementing them in the real world.

- Process optimization: Identify inefficiencies and bottlenecks in a virtual environment.

- Training and simulation: Prepare your team for various scenarios without disrupting actual operations.

Edge Computing

By processing data closer to its source, edge computing enables faster, more efficient analytics, especially for real-time decision making. Imagine processing data right where it’s generated, without the delay of sending it to a central server:

- Faster response times: Make split-second decisions based on real-time data.

- Reduced bandwidth needs: Process data locally, sending only relevant information to the cloud.

- Enhanced security: Keep sensitive data close to its source, reducing transmission-related risks.

Advanced Analytics Platforms

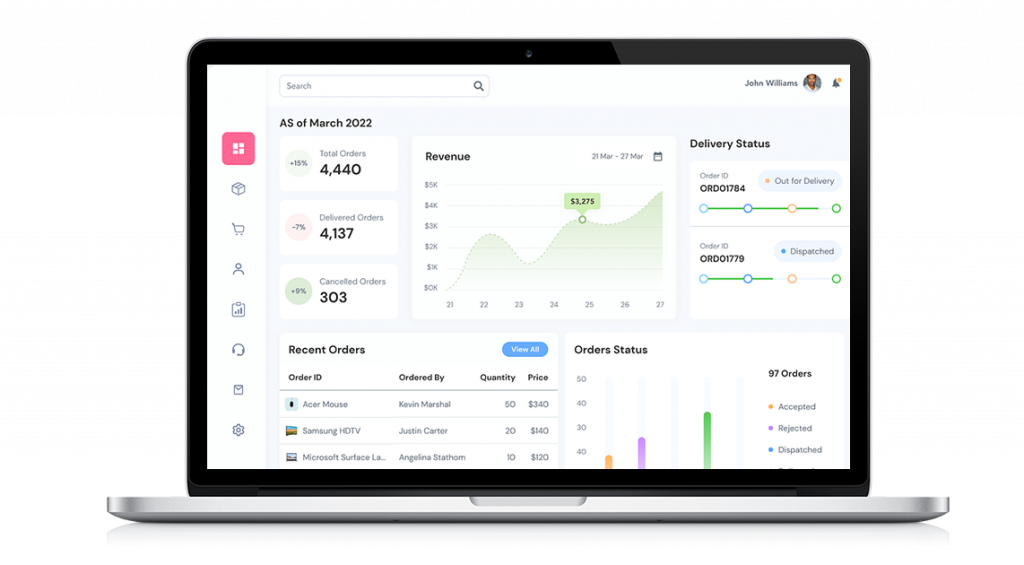

Picture having a user-friendly interface that puts the power of complex analytics into the hands of every decision-maker. That’s what analytics in manufacturing offers for your business!

- Democratized data access: Enable team members at all levels to leverage data-driven insights.

- Customizable dashboards: Tailor data visualizations to specific roles and needs.

- Integrated analytics: Combine data from multiple sources for a holistic view of your supply chain.

Read More: Manufacturing Analytics Software Development – From Concept to Implementation

By leveraging these technologies, you’re not just implementing supply chain analytics – you’re future-proofing your manufacturing operations. These tools work synergistically with analytics to provide deeper insights, faster responses, and more accurate predictions.

Contact us to implement these technologies in your manufacturing business!

The Implementation Process: Bringing Supply Chain Analytics to Your Manufacturing Operations

Now that you’re excited about the potential of supply chain analytics in manufacturing, you might be wondering, “How do I actually implement this in my factory?” Don’t worry – we’ve got you covered. Here’s a step-by-step guide to bringing the power of supply chain analytics to your manufacturing operations:

Assess Your Current Supply Chain Landscape

Assess Your Current Supply Chain Landscape

Before diving into supply chain analytics, it’s crucial to understand your starting point. This assessment phase involves:

- Mapping your supply chain: Identify all key players, processes, and data points across your entire supply network.

- Auditing existing data sources: Pinpoint where you’re currently collecting data, from supplier performance metrics to production line sensors and logistics tracking systems.

- Evaluating data quality: Assess the accuracy, completeness, and timeliness of your current supply chain data.

- Reviewing your IT infrastructure: Examine your current hardware and software capabilities. Do you have the necessary computing power and integration capabilities to handle supply chain analytics?

- Identifying data silos: Look for isolated pockets of supply chain data that aren’t currently integrated with other systems.

This assessment will help you identify strengths to build upon and weaknesses to address in your supply chain analytics strategy. You can leverage technology consulting services to streamline this step!

Define Clear Objectives and KPIs

Define Clear Objectives and KPIs

With a clear understanding of your current state, it’s time to set your goals. Consider:

- Specific supply chain challenges: What problems do you want supply chain analytics to solve? This could range from reducing lead times to optimizing inventory levels across your network.

- Measurable outcomes: Set concrete, quantifiable goals. For example, “Reduce supply chain costs by 20%” or “Improve on-time delivery performance by 15%.”

- Alignment with business strategy: Ensure your supply chain analytics objectives support your overall business goals.

- Time-bound targets: Set realistic timelines for achieving your objectives.

Remember, it’s often better to start with a few well-defined objectives rather than trying to solve everything at once.

Choose a Trusted Digital Transformation Services Company

Choose a Trusted Digital Transformation Services Company

Implementing supply chain analytics in manufacturing is a complex undertaking. Partnering with the right digital transformation services company can make all the difference. Look for a partner that:

- Has specific experience in custom manufacturing software development and data analytics services

- Offers end-to-end services, from strategy consulting to system integration and support

- Demonstrates a track record of successful supply chain analytics projects in manufacturing

- Can provide case studies and references from satisfied clients

- Has expertise in the latest supply chain technologies and analytics methodologies

A trusted partner will guide you through the complexities of supply chain analytics implementation, helping you avoid common pitfalls and accelerate your journey to data-driven manufacturing.

Develop a Comprehensive Supply Chain Data Strategy

Develop a Comprehensive Supply Chain Data Strategy

Work with your chosen partner to create a robust data strategy that includes:

- Identifying critical data points: Determine what data you need to collect across your supply chain to meet your objectives.

- Data collection methods: Implement IoT devices, sensors, and integration with supplier systems to capture real-time supply chain data.

- Data integration plan: Develop a strategy to bring together data from various systems – ERP, warehouse management, transportation management, supplier portals, and even external sources like market trends or weather data.

- Data governance framework: Establish policies and procedures for data quality, security, and compliance across your supply chain.

- Scalability considerations: Ensure your data strategy can grow and adapt as your supply chain analytics needs evolve.

You can easily streamline this step by using data consultation services!

Implement the Right Technology Stack

Implement the Right Technology Stack

Based on your data strategy, work with your digital transformation partner to:

- Select and implement a supply chain analytics platform: Choose a solution that can handle the volume, velocity, and variety of your supply chain data.

- Integrate with existing systems: Ensure seamless data flow between your analytics platform and other critical systems like ERP, MES, and CRM.

- Set up data visualization tools: Implement user-friendly dashboards that present key supply chain insights in an easily digestible format.

- Enable real-time analytics: Deploy systems that can process and analyze supply chain data as it’s generated, allowing for immediate action when issues arise.

- Incorporate advanced analytics capabilities: Implement predictive and prescriptive analytics models to forecast future supply chain scenarios and recommend optimal actions.

Develop and Deploy Analytics Models

Develop and Deploy Analytics Models

With your data infrastructure in place, it’s time to turn that data into actionable insights:

- Create predictive models: Develop algorithms that can forecast demand, predict supply disruptions, or optimize inventory levels based on historical and real-time data.

- Implement machine learning: Use advanced analytics techniques to uncover hidden patterns in your supply chain and continuously improve your models over time.

- Design scenario planning tools: Build capabilities to simulate different supply chain scenarios and their potential impacts.

- Establish alert systems: Set up automated notifications for potential supply chain issues or opportunities.

| APIs | GraphQL, RESTful APIs, EDI (Electronic Data Interchange) |

| ETL Tools | Apache NiFi, Talend |

| Databases | PostgreSQL, MongoDB, AWS S3, Azure Data Lake Storage |

| Data Warehouses | Amazon Redshift, Google BigQuery, Snowflake |

| Big Data Tools | Apache Hadoop, Apache Spark |

| Machine Learning | Tensor, PyTorch, scikit-learn |

| Business Intelligence Tools | Tableau, Looker, PowerBI |

| Stream Processing Tools | Apache Kafka, Apache Flink, Apache Kinesis |

| Monitoring Tools | Grafana, Prometheus |

| Encryption Tools | OpenSSL, AWS KMS |

| Compliance Frameworks | GDPR, ISO/IEC 27001 |

| Cloud Platforms | AWS, Microsoft Azure, Google Cloud Platform (GCP) |

Foster a Data-Driven Supply Chain Culture

Foster a Data-Driven Supply Chain Culture

The final step is ensuring your team can effectively use and benefit from your new supply chain analytics capabilities:

- Provide comprehensive training: Offer workshops and hands-on sessions to familiarize employees with new supply chain analytics tools and dashboards.

- Develop data literacy: Help all employees understand the basics of supply chain data analysis and interpretation, not just your data scientists.

- Encourage data-driven decision making: Lead by example and incentivize the use of data in daily supply chain operations and strategic planning.

- Create cross-functional teams: Bring together individuals from different departments (procurement, production, logistics, sales) to collaborate on data-driven supply chain projects.

- Establish a continuous improvement mindset: Regularly review and refine your supply chain analytics processes based on feedback and results.

Remember, implementing supply chain analytics in manufacturing is an ongoing process. Start with a pilot project, learn from your experiences, and gradually expand your capabilities. With persistence and the right technology partner, you’ll transform your manufacturing operations into a data-driven powerhouse, setting new standards for efficiency, responsiveness, and innovation in your industry.

Also Read: Discover how custom multi-warehouse inventory management software can revolutionize your supply chain with optimized operations and smarter inventory control.

Ready to Implement Supply Chain Analytics in Your Business? Get a Free Consultation!

Navigating the Challenges: Why Matellio is Your Ideal Supply Chain Analytics Partner

While the benefits of supply chain analytics in manufacturing are undeniable, the journey to implementation isn’t without its hurdles. But here’s the good news: with the right technology partner by your side, these challenges become opportunities for growth and innovation.

That’s Where Matellio Comes In!

Let’s explore the potential roadblocks and how Matellio’s expertise can help you overcome them:

Taming the Data Beast

Challenge: Ensuring data quality, consistency, and integration across your entire supply chain can feel like herding cats.

Matellio’s Solution: Our data consultation services bring order to chaos. We’ll help you clean, organize, and integrate data from every corner of your supply chain, ensuring you’re working with a single source of truth.

Bridging the Skills Gap

Challenge: Finding professionals who understand both advanced analytics and manufacturing processes is like searching for unicorns.

Matellio’s Advantage: Our team of data scientists and industry experts bring the perfect blend of analytical prowess and manufacturing know-how. Plus, we’ll train your team, building in-house capabilities for long-term success.

Winning Hearts and Minds

Challenge: Overcoming resistance to new technologies and data-driven decision-making can be an uphill battle.

Matellio’s Approach: We don’t just implement technology; we drive cultural change. Our change management expertise ensures your team embraces supply chain analytics, from the factory floor to the C-suite.

Untangling the Technology Web

Challenge: Integrating new analytics tools with existing systems can feel like solving a Rubik’s cube blindfolded.

Matellio’s Expertise: Our custom solution design and technology implementation services ensure seamless integration. We’ll make your new analytics tools play nicely with your existing systems, creating a harmonious tech ecosystem.

Fortifying Your Data Fortress

Challenge: With increased data collection comes increased security risks. Protecting your supply chain data can keep you up at night.

Matellio’s Shield: Our cloud integration services, and cybersecurity expertise ensure your data is locked down tighter than Fort Knox, while still being accessible to those who need it.

Proving the Payoff

Challenge: Demonstrating ROI, especially in the short term, can be as tricky as nailing jelly to a wall.

Matellio’s Approach: We help you identify and track the right KPIs from day one. Our user-friendly dashboards make it easy to visualize and communicate the value of your analytics investment.

Scaling New Heights

Challenge: Ensuring your analytics solution can grow with your business is like planning for a child’s future – you need to think ahead.

Matellio’s Vision: Our scalable solutions and continuous improvement services ensure your analytics capabilities evolve as your business grows. We’re not just solving today’s problems; we’re preparing you for tomorrow’s opportunities.

Conclusion– Navigate the Challenges with Matellio

Implementing supply chain analytics in manufacturing isn’t just about overcoming challenges – it’s about seizing opportunities. With Matellio as your partner, you’re not just getting a service provider; you’re gaining a collaborator committed to your success.

Our end-to-end approach means we’re with you every step of the way:

- We’ll design a custom solution tailored to your unique needs and challenges.

- Our technical expertise ensures smooth implementation and integration.

- We’ll develop advanced analytics models that turn your data into actionable insights.

- Our user-friendly dashboards make complex data accessible to everyone in your organization.

- We’ll train your team and provide ongoing support, ensuring long-term success.

- Our continuous improvement services keep you at the cutting edge of supply chain analytics.

But perhaps most importantly, we understand that supply chain analytics is just one part of your broader digital transformation journey. Our expertise extends beyond analytics to encompass your entire digital strategy, ensuring you’re prepared for the future of manufacturing.

With Matellio, you’re not just implementing a tool; you’re transforming your entire approach to supply chain management. We’re here to help you turn data into decisions, insights into action, and challenges into competitive advantages.

Ready to revolutionize your supply chain? Let’s embark on this journey together. Contact us today for a free 30-minute consultation!

FAQ’s

Q1. What specific technologies do you integrate for supply chain analytics in manufacturing?

Matellio integrates technologies such as AI, machine learning, IoT, edge computing, and advanced analytics platforms. These technologies enable real-time data processing, predictive analytics, and comprehensive data integration.

Q2. How does Matellio ensure data security and compliance during digital transformation?

We implement robust security protocols, including encryption, secure data transmission, and regular compliance audits. Our cloud integration services, and cybersecurity measures are designed to protect sensitive supply chain data.

Q3. Can you customize analytics solutions for different manufacturing industries?

Yes, Matellio provides tailored analytics solutions based on the specific needs and challenges of each manufacturing sector. Our approach includes customizing data models, dashboards, and analytics tools to align with industry-specific requirements.

Q4. What kind of support do you offer post-implementation?

We offer continuous support and maintenance services, including system updates, troubleshooting, and performance monitoring. Additionally, we provide training to ensure your team can effectively utilize the analytics tools and insights.

Q5. How does Matellio help in scaling analytics solutions as our business grows?

Matellio designs scalable solutions that can evolve with your business. We plan for future growth by building flexible systems that accommodate increased data volumes, additional data sources, and expanding analytics capabilities, ensuring long-term scalability and efficiency.

Enhanced Visibility

Enhanced Visibility  Improved Forecasting

Improved Forecasting Optimized Inventory Management

Optimized Inventory Management Streamlined Production

Streamlined Production Proactive Maintenance

Proactive Maintenance Enhanced Quality Control

Enhanced Quality Control Improved Supplier Management

Improved Supplier Management Optimized Logistics

Optimized Logistics Better Decision Making

Better Decision Making

Assess Your Current Supply Chain Landscape

Assess Your Current Supply Chain Landscape Define Clear Objectives and KPIs

Define Clear Objectives and KPIs Choose a Trusted Digital Transformation Services Company

Choose a Trusted Digital Transformation Services Company Develop a Comprehensive Supply Chain Data Strategy

Develop a Comprehensive Supply Chain Data Strategy Implement the Right Technology Stack

Implement the Right Technology Stack Develop and Deploy Analytics Models

Develop and Deploy Analytics Models Foster a Data-Driven Supply Chain Culture

Foster a Data-Driven Supply Chain Culture