The outbreak of COVID-19 has disrupted the logistics and transportation industry like nothing has ever before. The adoption of digitalization witnessed a sharp growth, where as many as 93% of decision-makers agreeing to make the necessary changes to digitalize their processes with technologies like AI/ML, RPA, and IoT.

RPA, or Robotic Process Automation, in particular, is known for bringing the most cost and process efficiency in the logistics business. Automating processes like invoice management, shipment tracking, inventory management, and after-sales services help logistics businesses achieve greater operational efficiency with huge cost savings. In this blog, we’ll highlight the most important ways RPA development services is transforming logistics and transportation, their respective benefits, implementation challenges, and ways to solve them too.

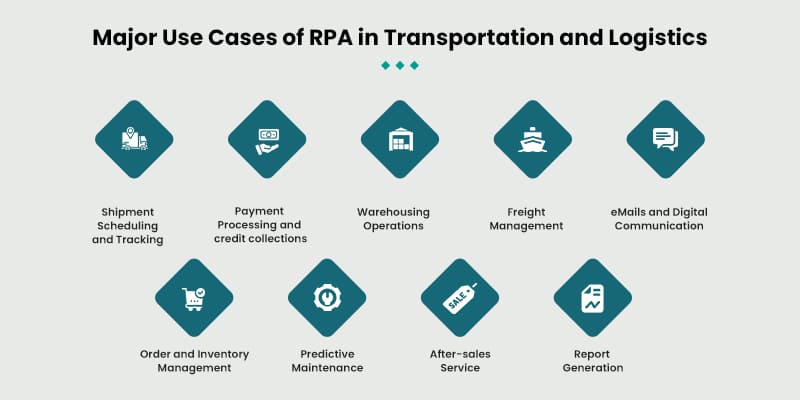

Major Use Cases of RPA in Transportation and Logistics

Transportation and logistics companies are constantly under pressure to remain competitive on limited budgets. Constant improvement in services to the reduction in costs is a feat that can be achieved without automation technologies like RPAs. Here is the list of major use cases of RPA that is helping the logistics industry achieve greater efficiency for improved net revenues.

Shipment Scheduling and Tracking

Creating shipment schedules is a huge part of a logistics business, one that requires a lot of time. However, since this is a recurrent task with very few variables changing frequently, RPAs can be used to speed up the process. The software can easily fill out the shipment forms with the recurrent information, perform optimization algorithms to pick the right transport option, and then even track the shipment from departure to its arrival at the destines location, making the entire process more efficient and accurate at all levels.

Payment Processing

Payment processing is yet another process for logistics companies that require flawless accuracy and speed to perform daily business seamlessly. RPAs can automate the processes like invoice creation, fetching important information from invoices to process payment, and then accurately organize to maintain records in a structured format. The end-to-end automation will speed up the payment-related operations quicker. And we’re saying it would perform operations that would otherwise take days to complete, in mere seconds.

Warehousing Operations

Most warehousing operations are repetitive in nature, including passing the details of supplies from one department to another, appropriate logging of inventory, generating tracking IDs, maintaining accurate manufacturing details, etc. These are the tasks that can easily be automated through RPAs. In fact, RPAs are more capable than any manual system to complete these tasks in large numbers and in less time, making the entire process an important use case for RPA-based automation.

Read More: How RPA Integration Solutions will Optimize BFSI Business Workflow?

Freight Management

Freight management is one of the most time and resource-consuming tasks performed by logistics companies. From load matching to packaging, the entire process requires decision-making capabilities at all levels making the process quite intensive and yet mundane. RPA bots can easily take over many of the freight management tasks and operate seamlessly 24*7. They can optimize the packaging, load shifting, carrier onloading, in the most efficient way by simply calculating the volume, area, and ither parameters of the orders. Such operations when completed by software bots not only consume less time, they complete it through improved effectiveness, ensuring zero wastage of resources and costs.

E-mails and Digital Communication

Logistics companies are required to function round-the-clock. While this is by itself achieved through the nature of the transportation industry, 24*7 availability for back-office processes can become an overhead expenditure for the business. The problem has become severe since most companies in logistics rely on their competitive prices to stay in the market against established companies. This is why RPA bots with rule-based troubleshooting, data fetching, and relaying capabilities can save the day for many logistics businesses. They will help them stay accessible on channels like emails, social media responses, and even live chatbots on their websites.

Order and Inventory Management

Staying competitive is the only means for transportation businesses to remain relevant. This is quite easily attainable through automation. RPAs can be placed at the inventory and transportation levels to keep the administration informed of the latest status updates. This would enable them to make decisions around purchase orders, returns, replacements, and supply orders as required, well ahead of time. This will help them minimize the transportation delays for their clients and then consequently achieve operational efficiency in inventory and order management.

Predictive Maintenance

Proactively preventing problems is one of the features through which RPAs are saving companies huge costs across various verticals. In logistics too, the RPA embedded to edge computing and smart sensors tools can quickly analyze remarkable changes in the functioning of an onloading and offloading equipment, transportation vehicles, and surveillance appliances. This way, they can automate the repair procedures to prevent outages and downtime.

Read More: How to Develop IoT Predictive Maintenance Solution?

After-sales Service

Whenever a customer calls a business about the delivery of their product, usually the support team fetches the required information from either their in-house system or requests the details through tracking ID on third-party servers. Both the processes can be time-consuming, which would limit the support staff from answering more pressing queries that would actually need human capabilities. RPAs trained to fetch such frequently required information from available sources can expedite such after-sales services for improved client satisfaction.

Report Generation

RPA in logistics helps suppliers, customers, and even drivers and other parties in generating real-time reports in the format required by the given user role. Report generation is yet another function that can be automated for improved accuracy and efficiency with the help of RPAs. The automated software used for this functionality would require NLP or Natural Language Processing capabilities to generate the report with the same available data for different contexts. What more? RPAs can also be used to extract information directly from various sources like social media, emails, and other web-based sources to generate more extensive reports for various stakeholders.

Key Benefits of RPA in Logistics Industry

In theory, RPAs are nothing but rules-based software robots that can handle repetitive tasks. However, the benefits associated with this one piece of technology are so many that they can contribute to up to 86% increase in productivity and 59 of cost-reduction. Here are some of the major benefits that RPAs offer to the logistics industry, to make such exponential growth.

Operational Efficiency

Operational Efficiency

For most logistics and transportation companies, automation is the defining factor for their success. It is no secret that beating competition through better services is the only means for logistics companies to thrive. As such, it is important that they invest in automation tools and software like RPAs to optimize cost-savings and improve the output quality and quantity of various processes.

This kind of operational efficiency is vital for them to scale their businesses in the most cost-effective manner. What’s interesting here is that unlike most other automation mediums, RPAs usually run alongside legacy systems. This means there are no costs or additional processes associated with data and application migration.

Now this is the kind of efficiency that every logistics workflow can benefit from, especially if it is not the core functionality of an organization. For example, in industries like healthcare and manufacturing, replacing legacy systems just to automate the supply chain processes is not an efficient option. Rather, embedding RPA in supply chain to assist these processes is a much better option that improves the working efficiency of the system without causing any huge disruption.

Cost Optimization

Cost Optimization

With operational efficiency comes the benefit of increased net revenues. The optimization of redundant processes ensures that no resources are hired to do the tasks that do not necessarily require unique human creativity and cognitive skills. As such, the same amount of work gets done with much less expenditure on the resources, which includes not only the remuneration but the workforce safety and operational infrastructure investments as well.

RPAs are also known to work faster and create much fewer errors than their traditional counterparts. This way, companies see a major improvement in the output of their logistics-related functionalities. For example, a human may not be able to work through multiple shipping options available, at least not on all the variables, but an RPA can perform this calculation really quick to strike the perfect balance between cost savings and service output. This helps them earn more profit through the same amount of investment, leading to increased cost optimization of the entire department.

Improved Accuracy

Improved Accuracy

In every culture there’s a saying that associate humans with their tendency to mess up. Errors are unavoidable in any human-centric procedure which can sometimes lead to huge losses. The processes of logistics industry are no exception. A simple error of identifier code, or a missing a deadline can snowball into major bottlenecks and flawed services.

RPAs solve that by automating the flow of important data and their processing through error-free procedures. Accurate scheduling of shipments, information updates to the senders and recipients, quality check at all the touchpoints, and transparency across the supply chain is something that humans have not been able to achieve until RPAs entered the image. This kind of accuracy in all divisions ultimately results in improved customer experience which consequently improves the brand value.

Read More: 7 Challenges in Logistics that AI Solves

Client Satisfaction

Client Satisfaction

As mentioned above, customer satisfaction is essential if one wishes to outgrow the competition, which is important for logistics and transportation businesses to thrive. Inaccurate delivery timeline, misplaced orders, delayed information, can all lead to dissatisfied clientele. And a disappointed client is much worse for a logistics business than any kind of operational block.

This is why automating processes that can benefit from accuracy and accessibility is a great way to earn customer trust in the long run. Through RPAs, many of the logistics processes can be expedited, making speed a USP for the brand. And in today’s times, when most things are available to the target customers almost instantaneously, speed is the key to achieving maximum client satisfaction, and eventually a brand image that grows revenues through sheer goodwill.

Enhanced Productivity

Enhanced Productivity

RPAs are basically small software robots that are made to function faster than their human counterparts. Tasks like scheduling, tracking, and report generation can take humans hours to complete. The reason being they have to collect information from various sources and then process all of that individually. Thereafter, assurance testing of their accuracy and then relaying it to different departments would also take time.

On the other hand, RPAs can automate the fetching of data directly to the processing engines. This would eliminate processes like requesting data, structural organization, comparison, and eventually evaluation. The RPAs can complete all these tasks almost the same instant data is entered anywhere into the system. This leads to complete optimization of the work process which improves productivity exponentially.

Data Sourcing for Analytics

Data Sourcing for Analytics

You don’t know what you don’t know—at least until you start gathering granular data about process efficiencies, thanks to your When in a process, humans tend to fix things like data fetching that create bottlenecks and then create a workflow around it. This method is good so long the same people are working on the given process. As soon as a member is replaced this human-centric approach backfires and creates new bottlenecks which could be harder to fix.

RPAs help in such scenarios by logging in the corrective measures. They can create a log of such problems and then eventually create semi-structured data that analytics engines can process to create important insights for business decisions. In addition to that, RPAs are also helpful in processes like data ingestion and cleansing from various sources, making it easy for other siloes in the department to get the required information in required formats.

Better Data Security

Better Data Security

Data security is essential for any logistics business, since it deals with so much confidential and business-related data that any sort of leakage can result in loss of business and trust. As such the rule-based functioning paradigm of RPAs comes in handy. With strict rules defining the flow of data, and no possibility of unauthorized intervention, RPAs can maintain better data security than most other core security measures.

The minimal human interaction in the process embedded with RPAs anyways ensure limited to negligible access to sensitive data. This way both accidental and deliberate data leakages can be minimized, which eventually helps businesses achieve greater compliance with data privacy laws too.

Challenges in Implementing RPA for Logistics

It is true that once implemented, RPA can reap a multitude of benefits for a logistics company. However, the process itself is not that easy. In fact, there are a number of challenges that almost all of businesses that adopt RPA for logistics purposes face. Here, we have listed the major challenges and how companies are tackling these.

Lack of IT Skills

Lack of IT Skills

Most logistics companies have resources that possess skills for traditional and manual management for fleet management, order processing, and load management. As far as the personnel in IT is concerned, they only usually have the necessary skills to manage the dashboard and generate reports for various workflows. This is simply not sufficient for the implementation of RPA. Hiring new resources with the desirable skills again becomes difficult since companies new to the arena do not always possess the information to audit the skills of candidates. The ideal solution here is to hire an AI services company. Partnering with such a company will not only ensure that you have the right skillset for RPA implementation, but also a resource that is already trained in the custom software solution built by the company.

Need for Standard Protocols

Need for Standard Protocols

RPA is a relatively high-level technology, implementation for which requires pre-defined workflows, clear structures and rules for communication. In the absence of standard protocols across organizations, RPA tools will not be able to function smoothly, requiring manual inputs at various levels. This will simply increase the new workload for the staff and negatively impact the overall productivity. By actively getting help from the IT head, and gradually implementing RPA in different siloes can prove to be helpful process here. This way the company won’t face any significant downtime, and eventually the entire organization can have interconnected rules and protocols for ceaseless functioning of RPA modules at various levels and use cases.

Rigidity of Robotic Process Automation

Rigidity of Robotic Process Automation

Often automation comes with a sort of rigidity in the processes. In fact, before the advent of deep learning and neural networks, most applications of AI in logistics were rather rigid and would function only given set of rules. There was no unsupervised learning that enhanced the cognitive capabilities of the AI tools to improve and scale processes as things change. Similarly, RPAs by their definition can only be used to function under a set of rules. Any change in functionality would either require reconfiguration or complete replacement with newer systems. This kind of rigidity can create barriers for the dynamic industry like logistics. This is why, ideally RPAs should be implemented for those tasks that require minimal decision-making needs. Minimal human interaction is in fact a requirement for the optimal use of RPA in transportation and logistics operations.

Change Aversion

Change Aversion

Since RPA is literally taking over the mundane and repetitive tasks from logistics operations, they are affecting organizational structures for multiple roles. As such an aversion to its adoption is inevitable. What companies can do to overcome this obstruction is train the existing staff for the newer roles like dashboard management, tools monitoring, predictive maintenance etc. This way they can retain the important staff members with long experience of the company’s workflows. Moreover, whenever human intervention is required for any kind of unforeseeable reason, the existing staff would easily take over the job to maintain workflow during the downtime.

Wrapping Up

Robotic process automation in logistics is transforming the sector for the better. Many organizations in the industry swear by the efficacy of the technology, in terms of accuracy of the procedures, improvement in productivity, and cost-savings. That being said, every new technology takes some time to show any measurable results. Similarly, adoption of RPA can prove to be a cost and resource consuming process, and the end results will have to be measured in the net effects.

This is also the reason why the decision to invest in RPA-based enterprise solutions should be taken with proper discretion. It would be best to hire an AI software development company with experience in the logistics and transportation industry. The ideal situation would be if the company also specializes in IoT development, since effective implementation of RPA in logistics & transportation would require integration and embedding of smart sensors and tools.

Matellio, with trackable experience in custom AI development for logistics businesses, is a trusted partner to build custom solutions for you too. Our AI developers and experts have ample experience and the required skills to build tailored RPA solutions for various logistics use cases. All you need to do is book a free consultation call with our experts to discuss the feasibility of your ideas with them. Alternatively, you can request to receive a free project plan and quote for the same. Simply fill this form with your requirements and our experts will connect base with you at the earliest.

Operational Efficiency

Operational Efficiency Cost Optimization

Cost Optimization Improved Accuracy

Improved Accuracy Client Satisfaction

Client Satisfaction Enhanced Productivity

Enhanced Productivity Data Sourcing for Analytics

Data Sourcing for Analytics Better Data Security

Better Data Security Lack of IT Skills

Lack of IT Skills Need for Standard Protocols

Need for Standard Protocols Rigidity of Robotic Process Automation

Rigidity of Robotic Process Automation Change Aversion

Change Aversion