Imagine a world where data isn’t just about numbers and figures. Instead, it’s a dynamic force that shapes the very core of your operations. That’s what precisely generative AI in manufacturing brings to the table. Doesn’t ring a bell yet? Well, this subset of AI doesn’t just crunch numbers. It interprets data in ways that empower you to make smarter decisions at every step of the product lifecycle, from design and engineering to manufacturing and beyond.

As a manufacturing business, you must know that manufacturing giant General Motors is already the generative AI leap. They are using tailored algorithms to optimize parts of vehicles and reduce their weight. The output? General Motors gets a bunch of different designs and then puts them through some virtual real-world tests. Finally, they end up with these super-efficient, lighter, and tougher vehicle parts that often won’t break the bank.

Looking at such transformative abilities, it is not surprising at all that global generative AI in manufacturing market size is expected to be worth around USD 6.3 million by 2032.

Now, as exciting as this sounds, we’re not here to paint a flawless picture. We know that integrating generative AI into your manufacturing processes can be challenging. It’s especially true if you are from a domain where communication and emotional understanding are paramount. But fear not, as in this blog, we’ll unravel everything you need to leverage this transformational technology for your business advantage. So, let’s dive in and discover new AI-based possibilities for your business.

Popular Tech Tools & Methods Used to Integrate Generative AI in Manufacturing

Practical Use Cases of Generative AI in Manufacturing: Services You Can Consider

While you may be overwhelmed with all the buzz about AI, we’re here to tell you that you’re well within the rights to select the type of generative AI development services that empower your business. Yes, you read that right. Manufacturing can be a complex domain because of its heavy reliance on technology. When it comes to generative AI, it’s not necessary to dive all in. As the technology offers several use cases, you can explore them and integrate them at your convenience. That said, here’s a list for you so that you can decide where to begin.

Generative Design Solutions

Generative Design Solutions

Do you want a one-stop solution for all your design and production needs? If yes, then it’s time to say hello to generative design solutions. This is a comprehensive solution that generates multiple design options that resonate with your business vision. Not only this, but it can also adhere to your technical as well as strategic limitations.

Thus, with generative AI, you can go beyond a static blueprint. That’s not all. This spectacular member of the AI family can roll out potential production scenarios. It can easily anticipate demand and fine-tune inventory levels. Again, these simulations are smart enough to consider every variable. From demand fluctuations to resource availability and supply chain intricacies, generative AI in manufacturing can do it all for your business!

Product Development

Product Development

Is your business at the mercy of expensive designers and technicians? Generative AI is here to save your day! This technology can save you from those long hours and costs you spend on product design and development. Besides serving you fresh and innovative designs, it can even cherry-pick the ones that best suit your business. It’s like having a digital toolbox filled with all the fascinating tech-based procedures– 3D printing, CAD software, smart algorithms, and digital twin simulations. All these become available at your fingertips.

Read More: Generative AI Applications: Everything You Need to Know to Get Started

Supply Chain Optimization

Supply Chain Optimization

Want to give a transformative boost to your supply chain operations? Try generative AI! This tech doesn’t just help create efficient supply chain models but also evaluates a bunch of critical factors like costs, delivery times, and reliability to make them perfect. What’s more? Generative AI in manufacturing is like having a super-smart assistant for your supply chain.

It can determine-

- Supplier risks

- Spots anomalies

- Find the quickest and most efficient routes for transportation, etc.

After integration, you’ll realize why it has gained a respectable name among digital transformation services that keep businesses one step ahead of the competition.

Quality Control Automation

Quality Control Automation

Generative AI steps up its game in making quality control a breeze for manufacturers. It’s like a vigilant AI system overseeing your production line 24/7. Sounds like a relief, right? By making real-time scrutiny available to you, AI doesn’t miss a beat. It spots defects as they happen and can even alarm you if you’re not around. However, this is possible if you also have IoT product development services in place. The best part? With generative AI, you dont have to worry about costly recalls or compromises in quality! Quality control automation powered by generative AI in manufacturing guardian angel, tirelessly working to deliver impeccable results, shift after shift.

Predictive Maintenance

Predictive Maintenance

Is your business prone to errors like equipment failure? Generative AI can be your savior! Indeed, you must have heard about predictive maintenance and early detection of problems. But you might not know the adaptive characteristics of machine learning algorithms. Generative AI solutions offer unique assistance for predictive maintenance as they can study everything about your equipment, technique, and processes. For instance, it can note and store the vibrations, movements, and temperature of your machinery. Based on all such information, generative AI in manufacturing can help you predict potential failures, allow for preventative maintenance, and reduce downtime.

Process Efficiency Improvement

Process Efficiency Improvement

The competition in the manufacturing industry is at a peak as the market has picked up the pace after the pandemic. In such a scenario, striking the right balance between efficiency and production can get quite challenging. Here, generative AI is a technology that can make you manage everything. So, for efficiency, a generative AI solution can-

- Train itself on vast amounts of historical and real-time manufacturing data.

- Can identify patterns, bottlenecks, and underutilized resources.

- Explore different scenarios, optimizing sequences, resource allocation, and automation options.

You can see that generative AI in manufacturing sets itself apart from legacy technologies in use in this field through its continuous learning process. It refines its recommendations over time, ensuring ongoing improvements. Thus, it can be your close aid, armed with all the nitty gritty knowledge for your manufacturing process.

Read More: 5 Ways AI Is Transforming The Manufacturing Industry

Customized Product Manufacturing

Customized Product Manufacturing

Tailoring a product as per your customer’s imagination is the new normal, especially for branding. Generative AI can bring this magic of personalization to your factories and inventories. It’s like having a digital artisan who can craft variations of your products to match individual tastes and needs, all without breaking a sweat. From customized car features to personalized gadgets, it can cater to several manufacturing needs. So, if you’re looking to stand out in a world of mass production and delight your customers with bespoke creations, it’s time to turn to generative AI.

Improved Customer Support

Improved Customer Support

Generative AI in manufacturing can upscale your customer support game. With smart chatbot integration, personalized email responses, and other methods, you can create an alter ego of your company assistant with this savvy technology.

It can talk to your customers just like a human, providing information and assistance 24/7. And the cherry on the top is that it’s a quick learner. With every chat, it gets better, resulting in super-customized support. Even when things get hectic – like during product launches – it handles the flood of inquiries like a pro.

Integrating generative AI-based solutions also means fewer human agents tied up in routine tasks. Hence, your employees will focus on other tasks of business importance. But here’s where it gets even more exciting. Generative AI can also be your data wizard. It gobbles up customer info like product usage, feedback, and preferences, spotting trends and potential issues. The data-driven insights lead to personalized service and product tweaks, keeping customers happy.

Material Selection Assistance

Material Selection Assistance

Are you willing to launch a new product, but you’re unaware of material intricacies? Generative AI in manufacturing can be your best mate when it comes to launching a new product line. This technology can judge how each material will perform in your specific product application, balancing performance with sustainability and cost. Moreover, it can act like a personal tailor for your product, customizing material choices to your unique needs. As we discussed in the earlier section, with each selection, your generative AI solution can get smarter, continuously learning and improving.

Machine Automation and Optimization

Machine Automation and Optimization

Generative AI in manufacturing is also helping upgrade technically backward equipment. It can tap into their data and analyze patterns. Moreover, generative AI optimizes machine parameters by iteratively adjusting settings to maximize efficiency while ensuring product quality. This iterative process refines operations over time, improving productivity and resource utilization. In essence, generative AI transforms manual machinery into smart, self-optimizing systems, streamlining manufacturing processes and enhancing overall operational efficiency.

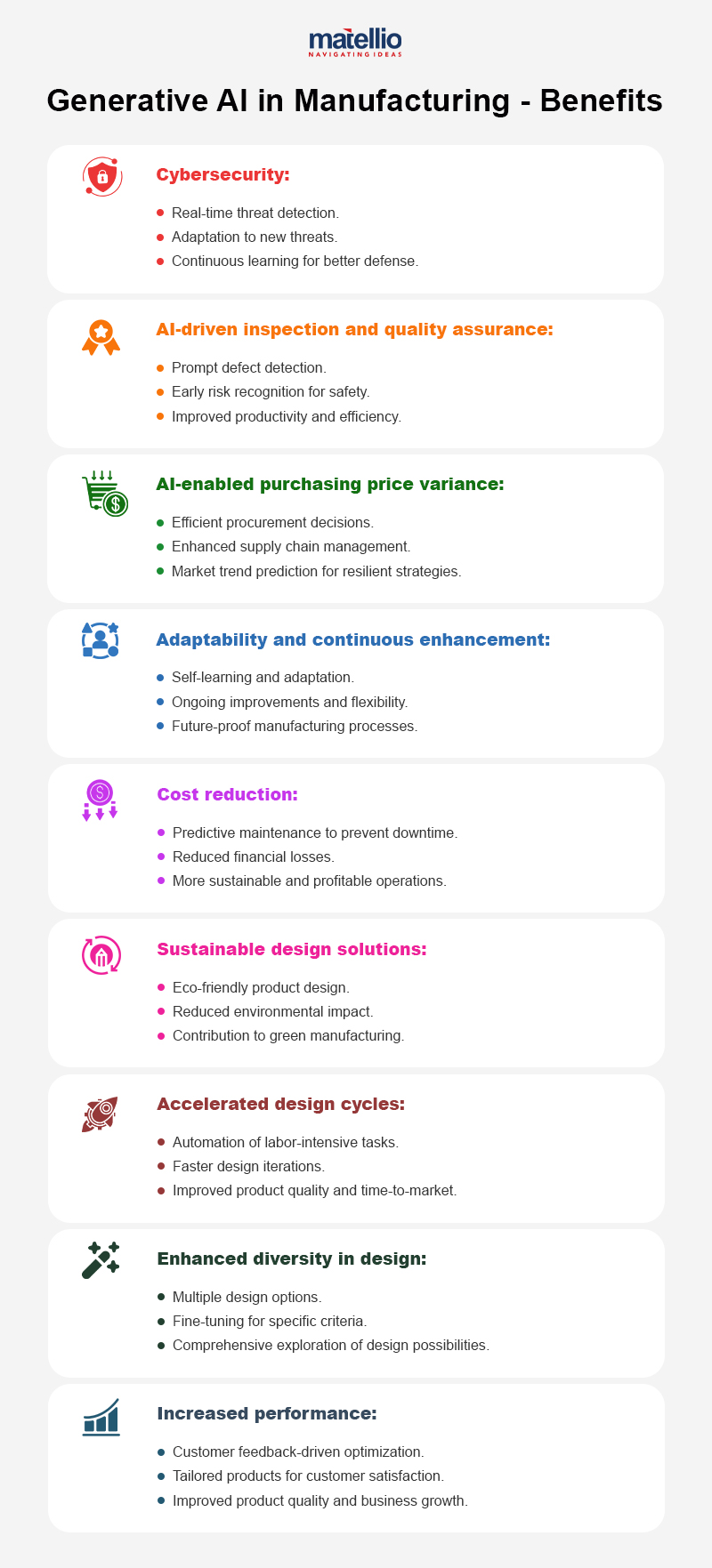

Benefits of Using Generative AI in Manufacturing

How to Seek Generative AI Development Services for Your Manufacturing Business?

If you were planning on how to approach generative AI expertise, your end stops here! AI is a revolutionary but still a new technology, yet to be explored. Under such circumstances, choosing the right AI development company or partner might seem confusing. But dont worry. Here’s a simple process that leads your generative AI journey straight to success.

Step 1: Initial Contact

Start by reaching out to some of the best AI development service providers like Matellio. Share your project ideas and requirements briefly.

Step 2: Discovery Meeting

Finalize a meeting to let your vendor dive deeper into generative AI in the manufacturing industry. This will just be about discovering your options to leverage this technology for your business advantage.

Read More: Generative AI for Business: Explore Use Cases, Industries, And Strategies

Step 3: Assessment & Proposal

Now, you have to ensure that your vendor assesses your project’s feasibility and complexity. After that comes the proposal—this will be a detailed document where all your requirements, timelines, and costs will be mentioned.

Step 4: Project Kickoff

Once you approve the proposal, your vendor will kick off the project. Ensure to take updates from them at every step.

Step 5: Model Training

This is a critical step for your generative AI integration. How the technology works for your business depends on this stage. So, ensure that the model training is highly tailored according to your business requirements.

Step 6: Testing & Optimization

Rigorous testing and optimization ensure that your model meets your expectations in generating desired outcomes.

Step 7: Integration

Now, you have to be a little vigilant and confirm that the solution you just got blends seamlessly with your existing systems or workflow.

Step 8: Training & Maintenance

Last but not least, as generative AI can be new for your team, ensure you seek proper training for them to use the tool effectively. Along with this, also tick the boxes for ongoing maintenance and support.

How Matellio Helps Use Generative AI in Manufacturing Business

Matellio, with extensive AI expertise, is your trusted partner to transform your manufacturing business through Generative AI. With years of experience, our team specializes in delivering successful next-gen solutions tailored to your unique manufacturing needs.

Our secret sauce? Customization. Matellio crafts AI solutions that seamlessly integrate with your processes, ensuring efficiency and productivity gains. Our agile approach helps you seek solutions that adapt and scale with your business. Besides all of this, our commitment to cost-effective manufacturing software development helps our clients harness the power of AI without breaking the bank.

So, have you decided how you want to leverage generative AI for your manufacturing business? Fill out this form and prepare to become the next industry icon!

Generative Design Solutions

Generative Design Solutions Product Development

Product Development Supply Chain Optimization

Supply Chain Optimization Quality Control Automation

Quality Control Automation Predictive Maintenance

Predictive Maintenance Process Efficiency Improvement

Process Efficiency Improvement Customized Product Manufacturing

Customized Product Manufacturing Improved Customer Support

Improved Customer Support Material Selection Assistance

Material Selection Assistance Machine Automation and Optimization

Machine Automation and Optimization