Manufacturing businesses are progressively focusing on simplifying their operations in order to boost profitability, expand margins, and deliver high-quality products to consumers on demand. Some manufacturing businesses employ every resource possible to stay competitive, the one technology that can genuinely help them: ERP implementation in the manufacturing industry.

The worldwide manufacturing market is anticipated to reach $117.7 billion by 2025, as per BCC Research.

Because of the expanding market size and fierce rivalry, ERP implementation services are required for small-to-medium manufacturing companies.

But,

What exactly is ERP software? What is the role of ERP in manufacturing industries?

Let’s check out!

So, let’s start!

What is ERP Management Software?

ERP is business software that enables a company to manage its operations through a system of interconnected apps. Product strategy, development, manufacturing techniques, financials, sales, and marketing are all incorporated into ERP software. ERP software and a shared database managed by a database management system provide a business with an integrated real-time picture of its essential business activities such as production, order processing, and stock control.

ERP software can handle business tasks like:

- Data management

- Quality control

- Product life cycle management

- Predictive analytics

- Compliance management

- Warehouse management

- Inventory management

- Billing & Invoicing

- Requirements planning

But, how is ERP transforming the manufacturing industry? Let’s check out!

ERP in Manufacturing Industry: Quick Overview!

An ERP system in a manufacturing industry enables businesses to obtain information at any time without disturbing the internal resources and procedures. ERP software improves product data management by providing improved managerial capabilities.

Product planning, work scheduling, monitoring, supply chain, and logistics are just a few manufacturing operations that can be automated with a full-fledged custom ERP solution. Consequently, the product innovation lifecycle is shortened, manufacturing efficiency is increased, and production time is reduced.

But,

When to Implement ERP System in the Manufacturing Industry?

For the booming manufacturing business, custom ERP software has emerged as the fundamental option.

The following are indicators that your company is willing for an ERP system:

- Communication lag

- Inefficient inventory management

- High operating costs

- Customer satisfaction continues to fade away

- Difficult to collect data from various departments

- Production downtime

- Increased resource wastage

As you’ve seen, some of the reasons for ERP implementation in the manufacturing industry; now, let’s move forward and discuss,

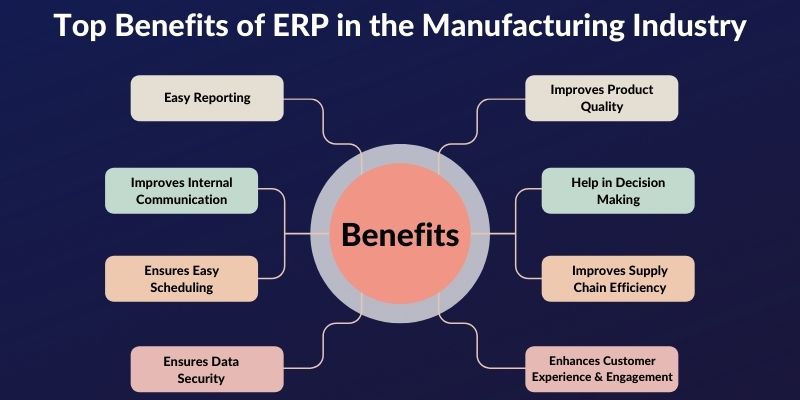

How are Manufacturing Industries Benefiting from ERP Implementation? Top Benefits of ERP in the Manufacturing Industry!

There’re many benefits of implementing ERP software in your manufacturing business. Among them are:

1. Easy Reporting

Many manufacturers have experienced the nightmare of unforeseen demand for a specific item. By creating forecast and sales projections based on previous inventory transactions, an ERP system can help you avoid these problems. This prevents extra inventory from piling up and the nightmare of being out of stock.

Furthermore, end-users can generate their reports rather than relying on the team to forecast future demand and material needs. User-friendly modules are simple to read and eliminate the possibility of making a mistake.

2. Improves Internal Communication

An ERP can significantly reduce reaction times by streamlining business procedures. As a result, internal communication across all departments within the business will improve, as will communication with all suppliers. This, in turn, has a good effect on collaboration among all parties. When everyone works together effectively, difficulties and objectives are addressed on schedule. As the ERP system responds quickly and efficiently to change, it significantly improves customer interactions. Without a doubt, this software is a highly effective solution that is constantly striving to improve business procedures.

3. Ensures Easy Scheduling

Materials entering the organization must be scheduled into production to ensure they are utilized when required and excess inventory doesn’t accumulate. Enterprise software aids in the purchase, pricing, and payments of raw materials and the scheduling of employees, and the operation and maintenance of machines to meet production deadlines. An ERP implementation in the manufacturing industry can also assist you in implementing a just-in-time sequencing method, in which items are ordered and used in a production schedule as they arrive.

4. Ensures Data Security

Engineers continuously look for security flaws as the pressure to secure and preserve data grows. A data breach can have disastrous financial consequences and damage to your brand. While current ERP systems are continually getting better software, outdated legacy systems aren’t being actively reviewed for security flaws.

5. Improves Product Quality

In the manufacturing industry, quality control is very important. An excellent Enterprise Resource Planning System allows a company to keep a close eye on its production quality. If a problem does arise, it is swiftly identified and resolved. Furthermore, improvements can be made to improve whatever quality component has deteriorated.

Organizations are no longer burdened with the hassle of discovering quality-related concerns after this fact. A manufacturer has the advantage of being able to respond to problems as quickly as feasible, thanks to an ERP System.

Also Read: Explore how tailored retail ERP software solutions can streamline operations, enhance customer experiences, and drive business growth through custom ERP development.

6. Help in Decision Making

A manufacturing company’s decision-making process can indeed be improved with the help of ERP software. It provides a complete view of every department within the organization and transparency, allowing them to make more informed, precise, and timely strategic decisions. ERP software provides access to an organization’s key performance areas by aligning them with predetermined goals and carrying out appropriate internal choices if they are required. The management can indeed optimize their everyday operations by having complete transparency to internal processes and departments.

7. Improves Supply Chain Efficiency

Manufacturers can use ERP software to ensure that the necessary process operates well and that client demand is satisfied on time. Coordination, purchasing control, stock management, and delivery of commodities are all features of supply chain management. Manufacturers may use this functionality to design better logistics strategies, which will help them save money on operating and administrative expenditures.

8. Enhances Customer Experience & Engagement

Manufacturers can improve the on-time delivery of their products to end customers by using accurate production schedules, inventory control, and adequate synchronization across the various distribution routes. Customer satisfaction is enhanced when products are delivered on time. Decision-makers can indeed get a realistic picture of inventories at any time thanks to ERP software that provides real-time data.

As you have the benefit of ERP in the manufacturing industry; now, let’s move forward and check,

Top Use Cases of ERP in the Manufacturing Industry!

Here are a few of the most common ERP use cases that help to enhance and streamline the manufacturing industry and organizations:

1. Supply Chain Management

The ERP software allows manufacturers to effectively manage product flows from manufacturing to consumers and returns and recalls. It increases their capacity to assist their consumers, for example, by regularly updating on when the order will be fulfilled and the exact cost. It also aids in anticipating future inventory or work time availability issues and making required changes to ensure seamless operation.

2. Resource Management

An ERP system assists businesses in managing and classifying their inventory, monitoring product flow, and providing full warehouse data management.

3. Quality Control Management

ERP systems assist manufacturing companies in managing their quality by storing non-compliant items and corrective actions in a centralized database. The businesses can handle the entire audit process, including planning, implementation, and follow-up.

4. Purchase Order Management

The ERP software manages raw material procurement, including supplier listings, quoting requests and assessment, purchase orders, stock updates, and other procedures. It works well with the supply chain management and Inventory modules. ERP solutions make it easier to work with approved vendors and contract manufacturers. Purchase orders and some other business transactions are made easier with ERP systems.

5. Finance Management

The finance and accounting modules are in charge of all accounting-related tasks. It keeps track of the business’s spending, balance sheets, and ledgers, continuous financial transactions with partners, tax management, and so on. This component is also used to store data from numerous audits that occur throughout the business regularly.

Moving on, let’s talk about,

Top Trends that will Dominate ERP Systems!

Take a look at a few of ERP’s upcoming trends:

1. Artificial Intelligence

AI in-built solutions connected with ERP systems in the manufacturing business help companies save time when evaluating large amounts of data. All of these duties are completed by AI, which sends notifications to the program. As a result, a more optimal and simplified business process can be achieved.

2. Cloud-Based ERP

Any computer or laptop with an internet connection can be used to access cloud ERP. As a result, the cost of hiring and paying IT staff is eliminated. It also helps managers watch and approve requests on time because of the mobility of the devices used. Cloud software is a subscription-based service that may be used by any number of employees for a low, inexpensive cost. For small enterprises, this is an added benefit.

3. Mobile-Based ERP Systems

Managers can use mobile apps to verify that operators follow production schedules, give repair orders on-the-job instructions, and monitor logistics operations in real-time, even when they are not on site. Because the ERP system is linked to all other departments, any changes made in mobile applications are quickly conveyed to all levels, ensuring that all employees are on the same line.

Conclusion

Custom ERP solutions help manufacturers overcome various issues and alter their businesses. They are responsible for fostering continuous improvement throughout an organization, making it more elegant, and preserving or extending its competitiveness.

ERP solutions have the ability to bridge the gap between today’s cutting-edge technology and traditional industrial procedures in the modern manufacturing landscape. Furthermore, an ERP system serves as a link between all functional areas in the manufacturing industry, bridging the gap and improving collaboration.

Contact us if you’re looking to expand, rebuild your business, or simply want to work more efficiently and eliminate errors. Matellio can create the ERP solutions you require. Our custom manufacturing software development services and track record assure that your software product is delivered on time and under budget.